2015-04-09

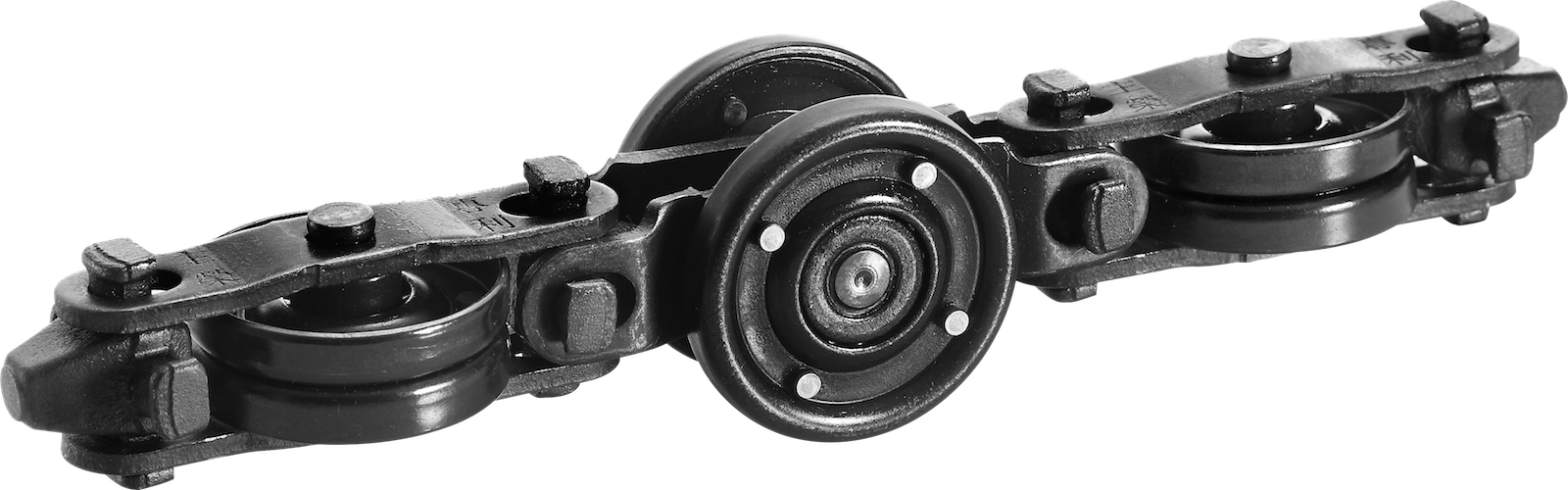

UH-7075 Overhead Conveyor Chain

About the traditional 5T chain:

At present, the traditional 5T conveyor chain (UH-5075) is the most widely used with largest sales number in overhead conveyor. The chain has the small pitch can run small curved track. Also it’s hanging more workpiece, many kinds of type for choice, great varietyof chain accessories and installation is easy. The 5T chain has always been the first choice of overhead conveyor. But this chain has gone through more than 60 years in the market. No matter in the produceing materials, processing methods and parts structure all have the very big improvement space.

For example, the transmission of 5T traditional conveyor chain has a defects, when the driver gear shifting gear and chain buckle arc surface touch driver unit. That will creating a downward pressure to cause the driver unit’s pressing plate (Pressing device) and bottom plate damage. And complex chain components to making the tolerance increase, processing tedious and difficult assembly then increase chain manufacturing difficulty.caused the occurrence of defective parts. Effect of conveyor operation and using life of chain.

We created UH-7075 5T cross type overhead conveyor chain.

According to the traditional 5T chain for overall reform, Is not only change the new appearance, The most important is the mechanical properties are greatly improved.The features are as below:

1. The perfect compatibility with traditional 5T accessories:

The driver unit, horizontal curved track, vertical curved track and hanger are 100% compatibility with traditional 5T conveyor.

2. More streamline of shape and structure:

Strengthened the steering structure: Forging cross-head as main part of steering, so the chain to become a real universal structure. When the chain conveying to the horizontal & vertical track, the chain would not distorted and offset the track. Also reduce the wear and resistance.

3. The tensile strength increased dramatically:

Except the chain wheels & rivet which are independent of tensile strength.All the other parts are made of middle carbon steel in model S45C with quenched hardening treatment. The chain would not deformation in strong tension and the conveyor chain reduce the elongation about 50%.

4. Efficient design of driving:

Improved the chain’s transmission of structure, to reduce the component force substantially of driving direction. And make the driver gear more efficient to pushing the chain, so the conveyor line running more fluent, energy saving and the using life of driving unit also extend.

5. Lightweight, flexible and more energy saving:

The new 5T cross-type chain, improve the old problems and strengthen many mechanical properties. While also reducing the weight of 8% to reduce the force of chain, the load of conveyor motor becomes small and less power consumption, The design fully meet of environmental protection and energy saving.

UH-7075 chain in all respects with excellent performance. It is the best choice of overhead conveyor chain.

UH-7075 outstanding performance with unprecedented in every respect, the absolute is currently the best choice in conveyor chains.

About the traditional 5T chain:

At present, the traditional 5T conveyor chain (UH-5075) is the most widely used with largest sales number in overhead conveyor. The chain has the small pitch can run small curved track. Also it’s hanging more workpiece, many kinds of type for choice, great varietyof chain accessories and installation is easy. The 5T chain has always been the first choice of overhead conveyor. But this chain has gone through more than 60 years in the market. No matter in the produceing materials, processing methods and parts structure all have the very big improvement space.

For example, the transmission of 5T traditional conveyor chain has a defects, when the driver gear shifting gear and chain buckle arc surface touch driver unit. That will creating a downward pressure to cause the driver unit’s pressing plate (Pressing device) and bottom plate damage. And complex chain components to making the tolerance increase, processing tedious and difficult assembly then increase chain manufacturing difficulty.caused the occurrence of defective parts. Effect of conveyor operation and using life of chain.

We created UH-7075 5T cross type overhead conveyor chain.

According to the traditional 5T chain for overall reform, Is not only change the new appearance, The most important is the mechanical properties are greatly improved.The features are as below:

1. The perfect compatibility with traditional 5T accessories:

The driver unit, horizontal curved track, vertical curved track and hanger are 100% compatibility with traditional 5T conveyor.

2. More streamline of shape and structure:

Strengthened the steering structure: Forging cross-head as main part of steering, so the chain to become a real universal structure. When the chain conveying to the horizontal & vertical track, the chain would not distorted and offset the track. Also reduce the wear and resistance.

3. The tensile strength increased dramatically:

Except the chain wheels & rivet which are independent of tensile strength.All the other parts are made of middle carbon steel in model S45C with quenched hardening treatment. The chain would not deformation in strong tension and the conveyor chain reduce the elongation about 50%.

4. Efficient design of driving:

Improved the chain’s transmission of structure, to reduce the component force substantially of driving direction. And make the driver gear more efficient to pushing the chain, so the conveyor line running more fluent, energy saving and the using life of driving unit also extend.

5. Lightweight, flexible and more energy saving:

The new 5T cross-type chain, improve the old problems and strengthen many mechanical properties. While also reducing the weight of 8% to reduce the force of chain, the load of conveyor motor becomes small and less power consumption, The design fully meet of environmental protection and energy saving.

UH-7075 chain in all respects with excellent performance. It is the best choice of overhead conveyor chain.

DONG GUAN CHU RONG CONVEYOR CHAIN CO., LTD.

NO. 21, XINTANG RD., HENGLI VILLAGE, HENGLI TOWN, DONGGUAN CITY, GUANGDONG PROVIDENCE, CHINA

Tel:+86 769 21660293

E-Mail:sevice@churong-chain.com